What is OEE?

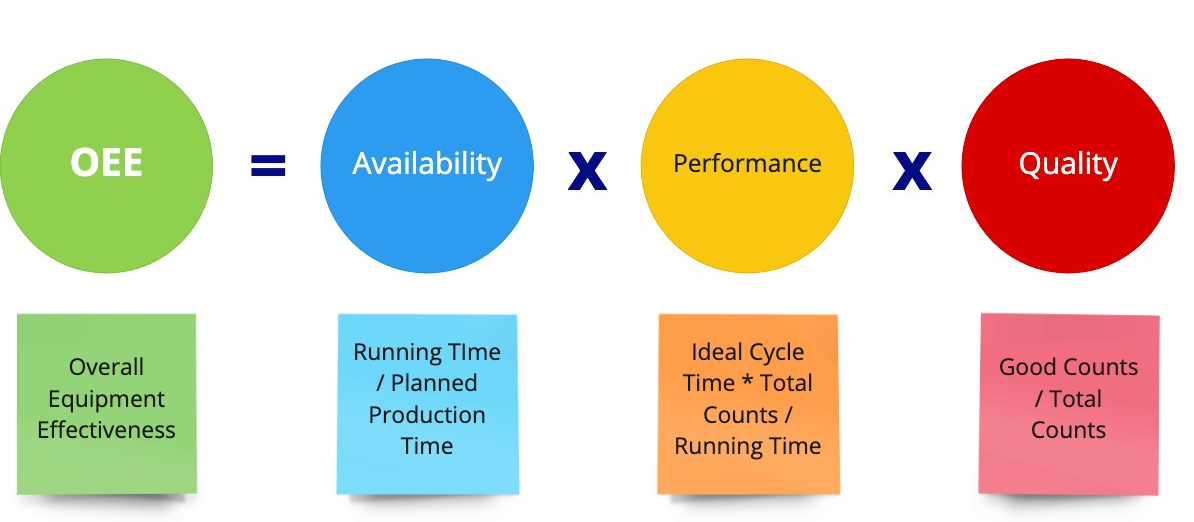

Overall Equipment Effectiveness is a very important KPI to provides a clear picture of your factory’s efficiency by evaluating three critical factors:

Availability: Track uptime of equipment and identify downtime causes.

Performance: Measure speed and efficiency of production processes.

Quality: Ensure products meet quality standards right from first pass.

Order two devices or more and get 20% discount Now

How It Works

Collect

Collect accurate data from machines' sensors, signals, or our provided sensors

Display

Display production data instantly on a dashboard accessed from anywhere

Report

Receive conditional alerts and automatic reports per shift, day, MTD, and monthly

Analyze

Analyze and integrate data to provide valuable insights to support in decision making

Main Benefits

- Identify Bottlenecks: Pinpoint areas causing delays and inefficiencies.

- Improve Productivity: Enhance production speed and reduce waste.

- Ensure Quality: Maintain high standards and reduce rework.

- Real-Time: Gain complete real time visibility into operations.

- Easy to integrate with other systems to receive and send data

- Minimize paperwork

- Automatic Reports: on time with analysis

- More Engagement: Increase teams engagement and motivation.

- Fair operators performance and rise man of the day and month automatic.

- Track historical data fast.

- Enhance Quality: Maintain high quality and reduce rework.